Pro Wash/Dry

Multistage Automated Washing System Designed for Dental 3D Printing

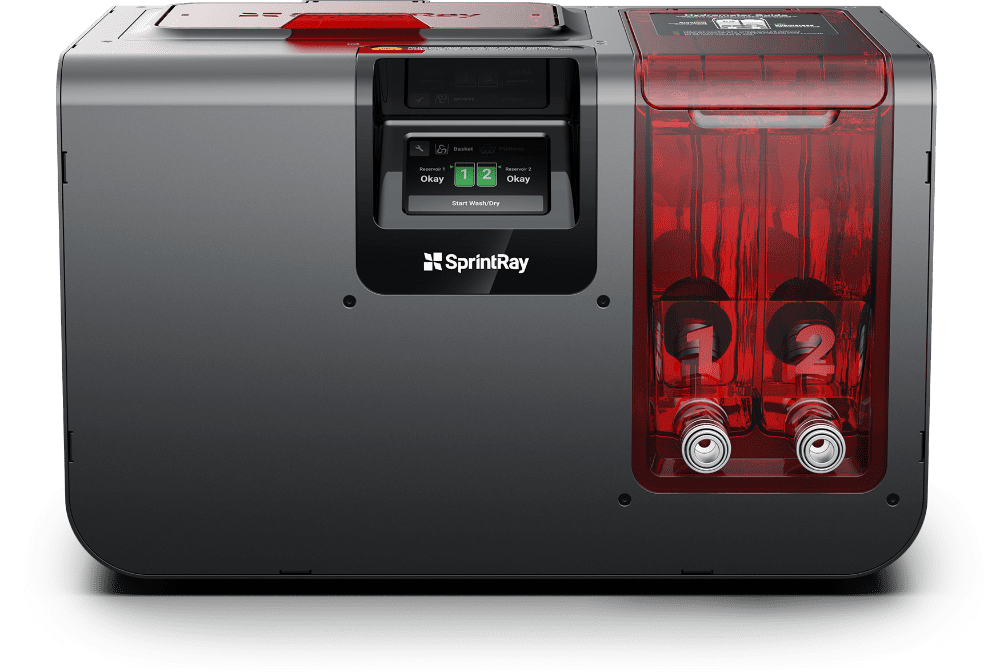

The SprintRay ProWash/Dry is the first fully automated, two stage wash and dry system built to deliver the speed, cleanliness and ease of use demanded by both clinics and laboratories. Using a patented mechanical jetting system with a high speed motor spinning at over 10,000 rpm, the ProWash/Dry is able to complete a full two stage wash cycle in less than 10 minutes.

Fast

Pro Wash/Dry uses mechanical jetting to rapidly deliver IPA to printed parts. This unique method provides excellent of agitation, reducing wash duration while offering improved cleaning power.

Clean

Thanks to a suite of automatic features, the only time you have to touch IPA is when you pour it into the reservoirs. Automatic pumps recycle alcohol, and quick-connect hoses whisk it away.

Easy

Pro Wash/Dry was designed with input from the dental community. Inspired by DIY kits all over the world, we leveraged the latest technology (and invented some of our own) to deliver a superior washing experience.

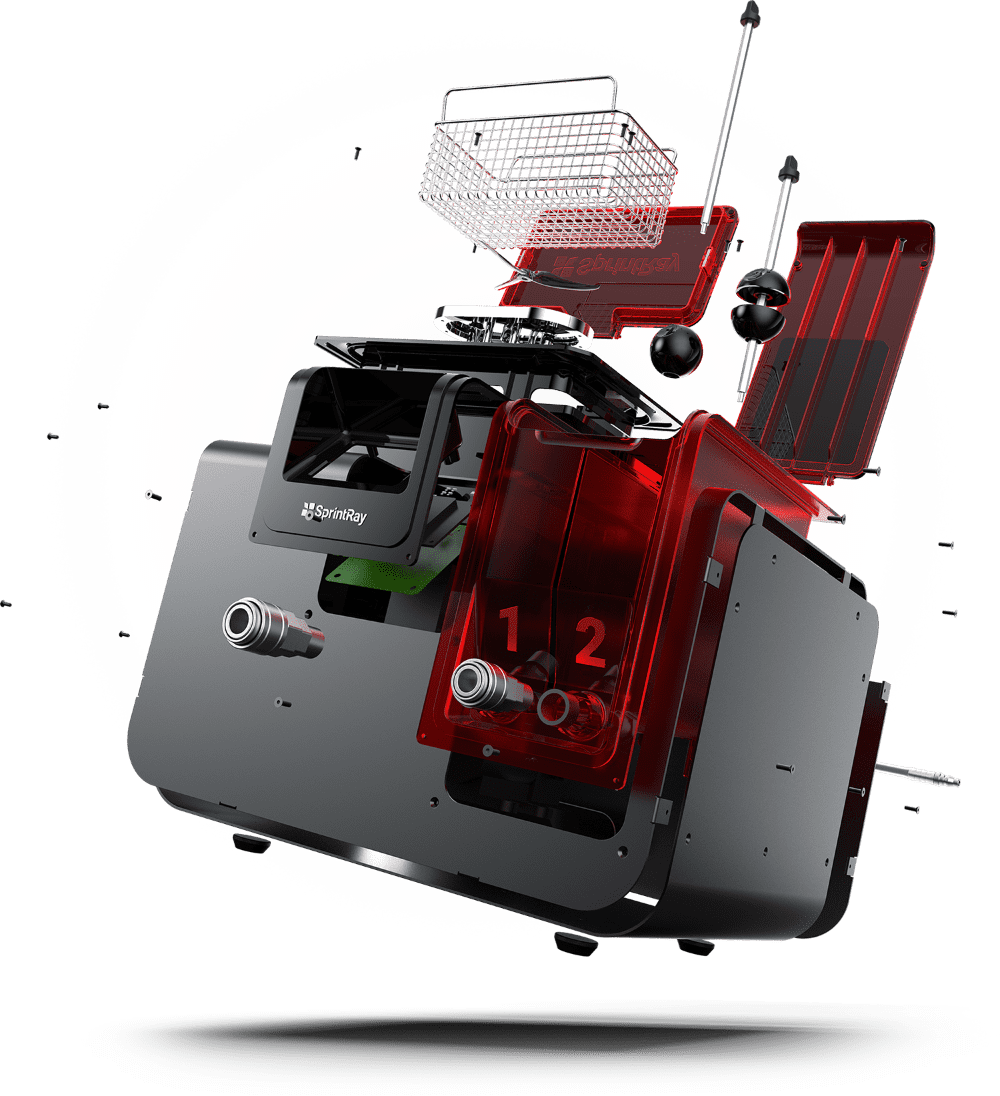

Mechanical Jetting: As Fast as it Sounds

Fluid Mechanics: The Stuff of Patents

You’ve never washed parts like this before. Thanks to its high-powered motor, precisely manufactured propeller, and innovative alcohol delivery method, Pro Wash/Dry can complete a full two-stage wash and dry in less than nine minutes.

10 Minutes Wash/Dry

SPRINTRAY PRO WASH/DRY

AUTOMATED BUCKET WASH

ULTRASONIC CLEANER

2 Cycle Wash + Rapid Dry

Submerging your parts in IPA can get the job done, but it results in a lot of waste alcohol. Pro Wash/Dry uses a patented method to agitate and clean without full submersion. The result: cleaner parts, less waste, and faster workflows.

3 Cycles, One Touch

Set and Forget: Hands-free Process

Pro Wash/Dry was built to be used with SprintRay Pro. Once your print job is finished, simply place your platform in the cradle and press ‘Start’. Pro Wash/Dry will automatically perform a two-stage wash and then dry your parts.

Effortless Speed

Dirty Job, Clean Workstation

Efficiency to Write Home About

Pro Wash/Dry can operate with a little as a half-liter of alcohol thanks to the unique way it delivers IPA to your parts. It’s a small victory for your pocketbook, a big win for the environment, and a quantum leap in 3D printing wash efficiency.

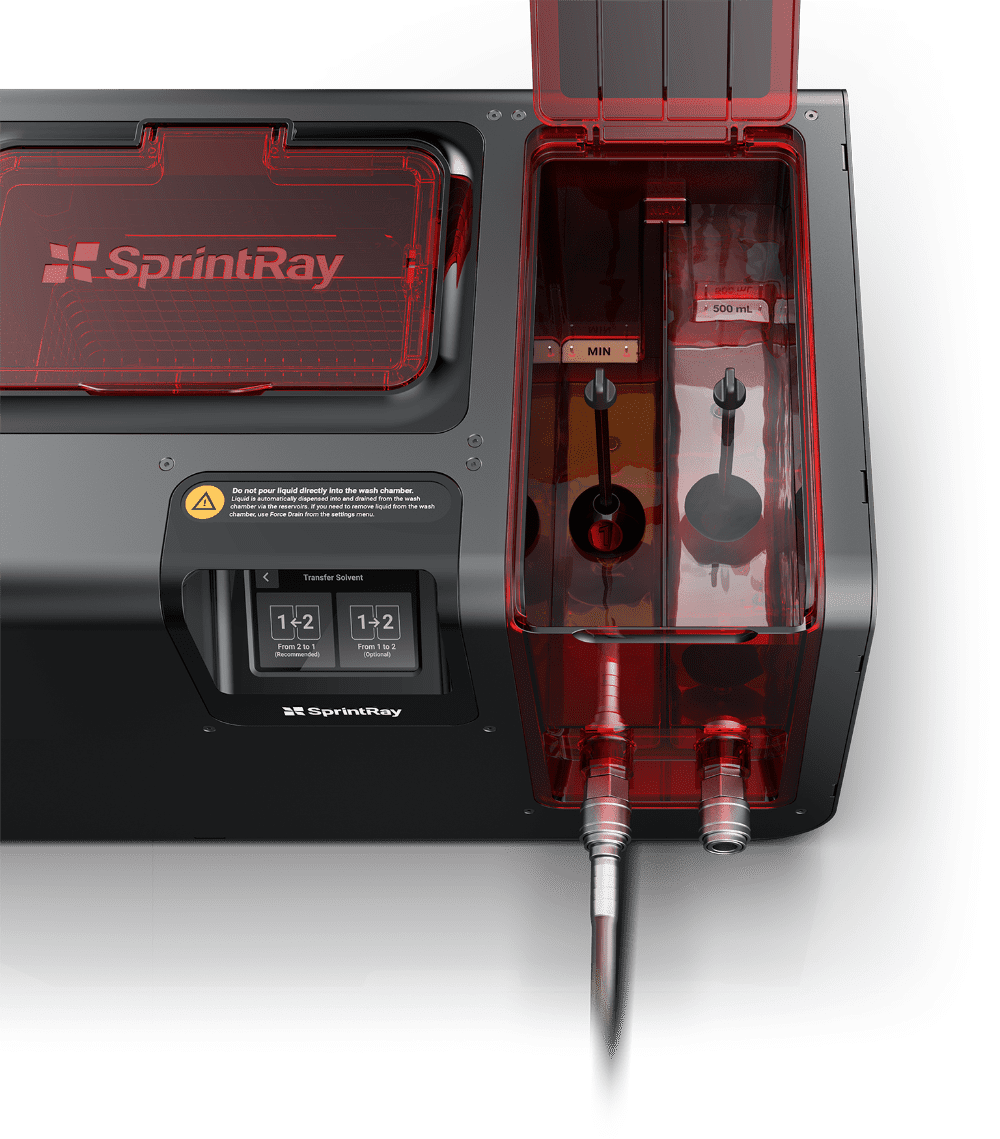

500mL to Start

Touchless Alcohol Recycling

Advanced electronics and mesh-wire plumbing connect all the chambers in Pro Wash/Dry. Recycle dirty alcohol from one chamber to the other with the press of a button. No mess required.

Reduced Waste

Quick-connect IPA Draining

To drain IPA from Pro Wash/Dry, we’ve provided a quick-connect hose. It snaps into place, creating a water-tight seal instantly. When you’re finished draining, simply press the release ring to instantly stop the flow.

Clean IPA Removal

Easy to Use, Easy to Own

We know that one of the most precious resources in a dental clinic is time. So in addition to making Pro Wash/Dry run an extremely fast cycle, we made it dead simple to operate. If your staff can operate a smartphone, they can use Pro Wash/Dry with very little training. And to reduce maintenance, we sourced innovative materials that are resistant to chemicals.

Industrial Grade Materials

Made with an aluminum chassis and chemical-resistant, translucent plastic, Pro Wash/Dry requires almost no maintenance.

Shrouded Control Panel

To prevent chemicals from dripping onto the touchscreen computer, we set the electronics back under a small shroud. One less thing to worry about.

Automatic Wash Mode Detection

Pro Wash/Dry was designed to fit the SprintRay Pro build platform. But when you need to wash loose parts, simply insert the basket, close the lid, then hit start.

Automatic Stop/Start Failsafe

If you remove the platform or open the lid during a wash cycle, you don’t have to worry about creating a mess. Automatic Stop safeguards your workspace.

Fill Level Sensors

Pro Wash/Dry knows how much IPA it has in each chamber, so if there is insufficient volume it will gently remind you to add more.

Overflow Protection

With extra tolerances built-in to the reservoir designs and sensors monitoring fill levels, you’ll feel confident no matter who uses Pro Wash/Dry.

Technical Specifications

| Platform Wash Envelope | 17 x 12.7 x 7.6 cm 7 x 5 x 3 in |

|---|---|

| Basket Wash Envelope | 17 x 12.7 x 12.7 cm 7 x 5 x 5 in |

| Liquid Level Monitoring System | Conductive Sensor |

| Liquid Saturation Monitoring System | 2 Pre-calibrated Hydrometers |

| Wash Liquid Compatibility | Isopropyl alcohol 91% (Recommended) Isopropyl alcohol 99% Ethanol |

| Liquid Disposal Method | 2 Standard Quick Connect Drain Ports 1 Quick Connect Drain Hose with Automatic Cut-off |

| Wash Liquid Capacity | 2 liters per reservoir |

| Minimum Wash Solution Required | 500 mL Per Reservoir |

| User Controls | 3.5″ color touch-screen Pre-defined Wash/Dry preset |

| System Controls | Microcontroller with upgradable firmware via USB |

| Safety Sensors | Automatic Start/Stop Sensors Platform vs Basket Detection Fill Level Sensor |

| Power Requirement | 100–240v (Via DC Adapter) |

| Dimensions | 30 x 30 x 46 cm 12 x 12 x 18 in |

| Packaging Dimensions | 36 x 36 x 50 cm 14 x 14 x 20 in |