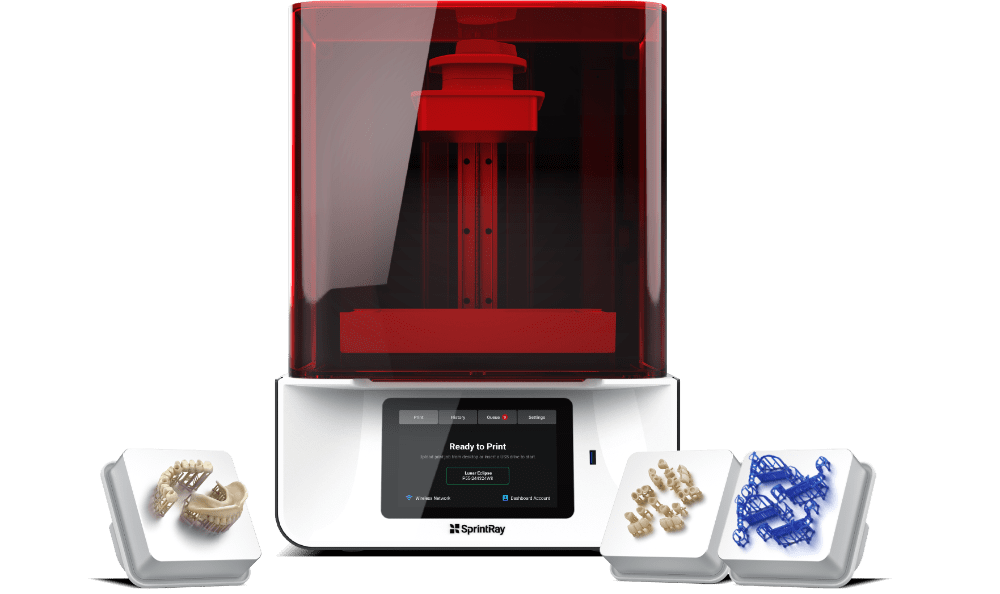

SprintRay Pro Dental 3D Printer

Digital Dentistry Comes of Age

SprintRay Pro represents an awesome step in technology towards fully digital dentistry

3D printing in dentistry is much more than just a new technology: it has the potential to control costs, improve flexibility, and expand the scope of patient care. To deliver on this potential, we made SprintRay Pro the most user-friendly, powerful and reliable desktop 3D printer in dentistry. Because the technology in your office needs to solve problems, not create headaches.

Massive Print Throughput

With Pro, you can delight your patients with same- and next-day deliver of all kinds of appliances. Print up to 30 full-arch dental models in a single batch on Pro95.

Born, Reborn, Re-reborn

Always on the cutting edge, Pro is continuously updated with new features and improvements. It will be the newest thing in your office for years to come.

Open Certified Materials

Our unique resin ecosystem allows you to leverage the industry’s greatest innovations, whether they come from us or one of our materials partners.

Unmatched Fit & Finish

SprintRay Pro is built with the world’s best materials, and leverages the world’s most advanced software, to offer unbelievable accuracy and surface quality.

The world’s most advanced desktop 3D printer.

Every detail crafted for dentistry.

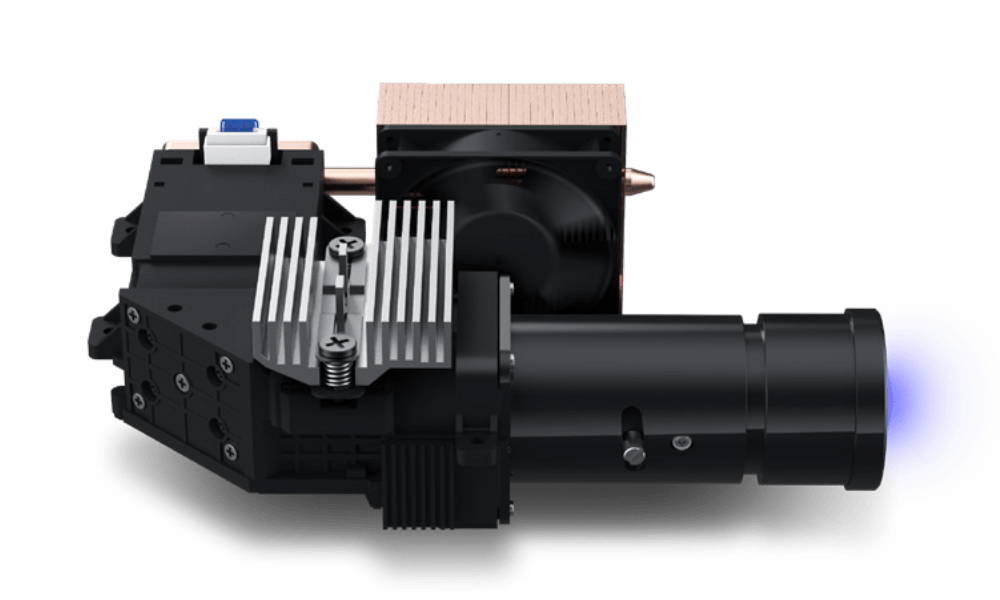

Breakthrough tech, breakneck speed.

The custom projector used in SprintRay Pro delivers high-intensity light uniformly across the entire build surface. Developed specifically for 3D printing, each projector’s output is checked at key points across the build surface for accuracy measured down to the individual pixel. It’s the only way to ensure a perfect, accurate print. Every single time.

405nm LED

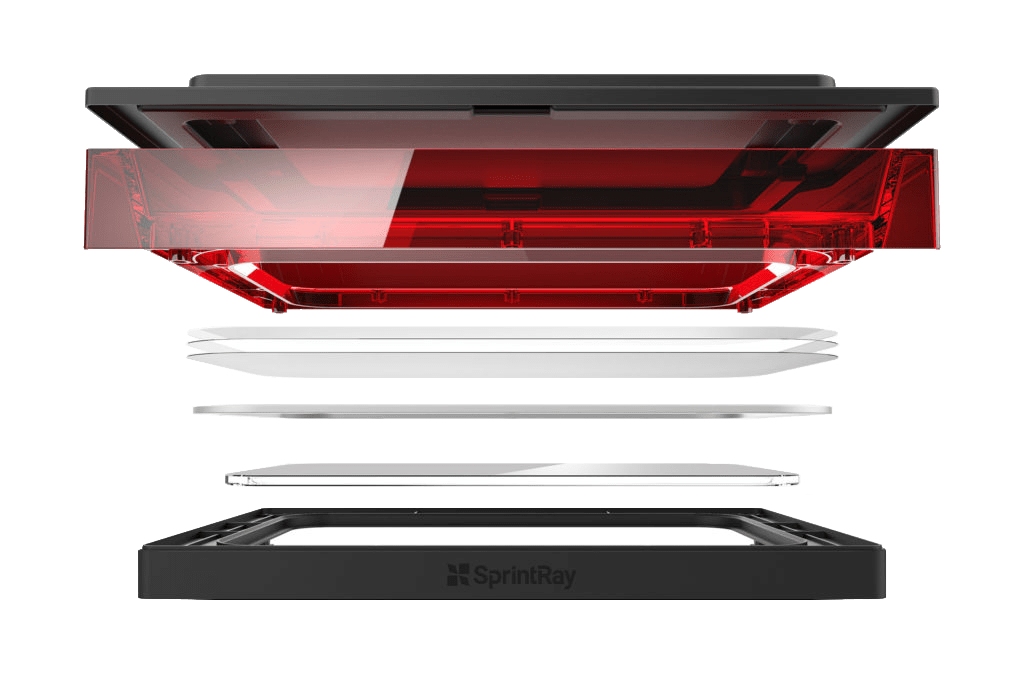

STEM Tank simplifies and adds speed.

SprintRay introduces another key innovation with proprietary STEM Tank™ technology. The STEM (Selectively Textured Elastomeric Membrane) Tank introduces air between the resin and tank floor to minimize adhesion, then uses elastic displacement to separate the printed layer from the tank. The result is a dramatic improvement in speed and reduce mechanical complexity.

60% More Capacity

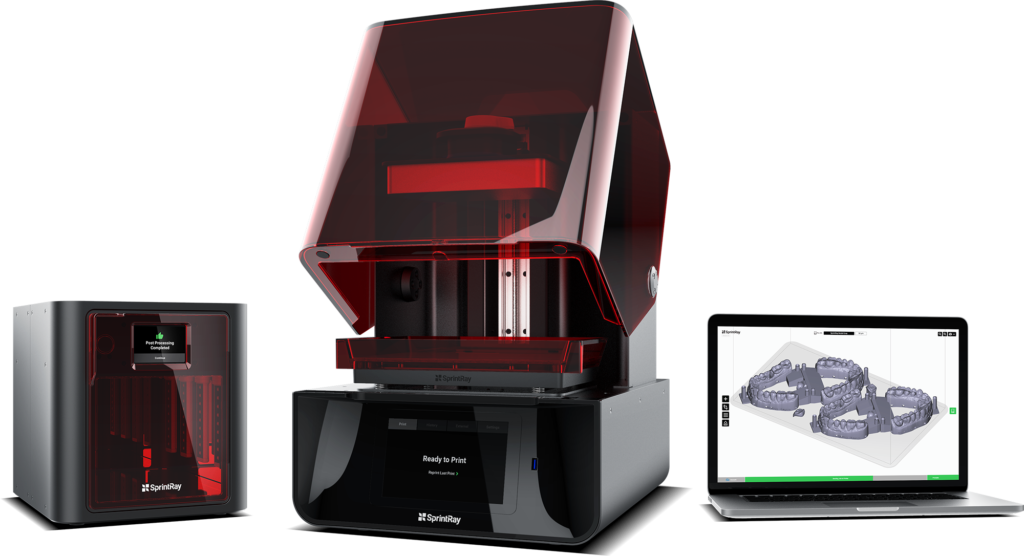

Complementary Pairs

Full coverage for all types of in-office dental manufacturing.

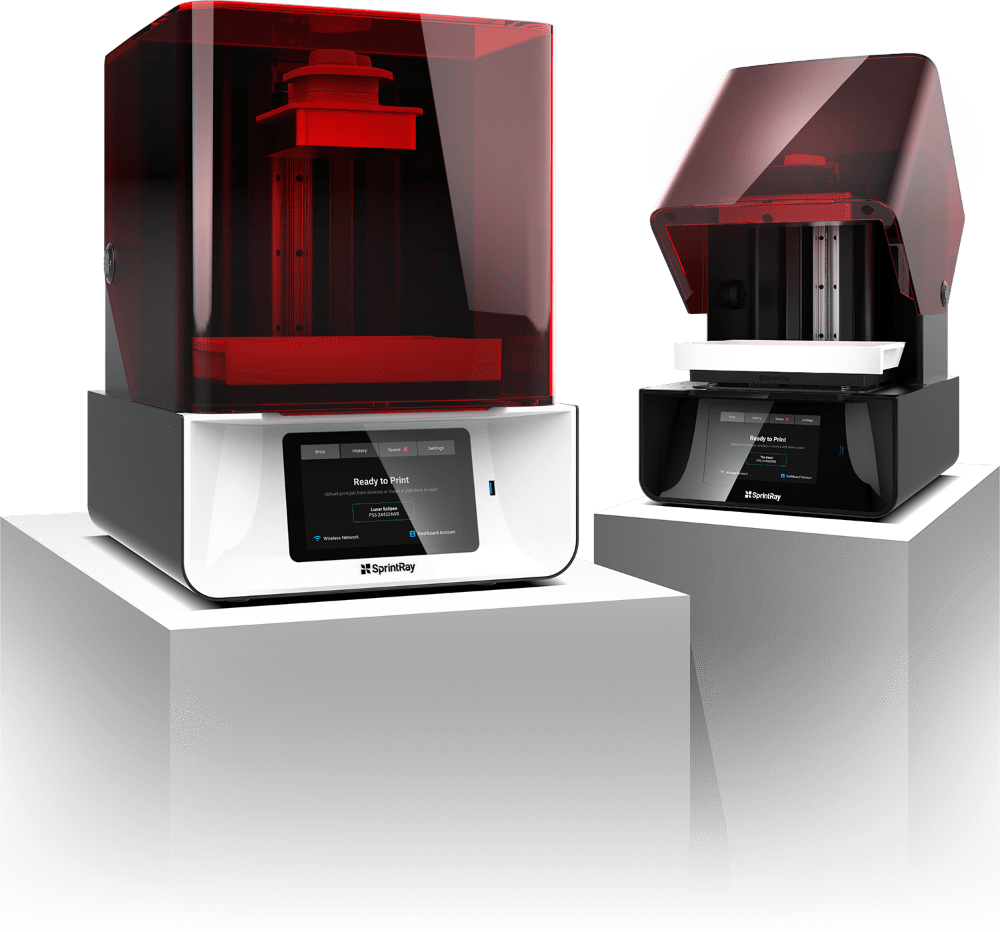

SprintRay Pro 95

Accurate production and high throughput for all manner of dental appliances.

SprintRay Pro 95 is the perfect 3D printer for dental offices that want to deliver on the promises of in-office production. Featuring unmatched throughput, high accuracy, and a high flexibility, Pro95 is the right choice for most dental practices. Incredible accuracy, repeatability, and user-friendliness means you can always deliver an outstanding patient experience.

SprintRay Pro 55

Incredible precision makes this unit ideal for restorative applications.

A 55-micron XY pixel size and Pixel Toning brings industry-leading accuracy to Pro 55, making it perfect for jobs that require razor-thin margins such as temporary and definitive crowns, hybrid dentures, and more. Pro 55 is the ideal printer for clinics or labs that specialize in restorative applications, reducing treatment cost and delivery times while improving your workflow.

- Surgical Guides

- Study and Wax-up Models

- Models for Aligner Production

- Indirect Bonding Trays

- Digital Dentures and Try-ins

- Occlusal Guards

- Surgical Guides

- Temporary and Definitive Crowns

- Hybrid Dentures

- Cast Applications

Industry-leading Materials

SprintRay resins offer fantastic value for money. For maximum flexibility, we also certify top industry brands to work with our printers.

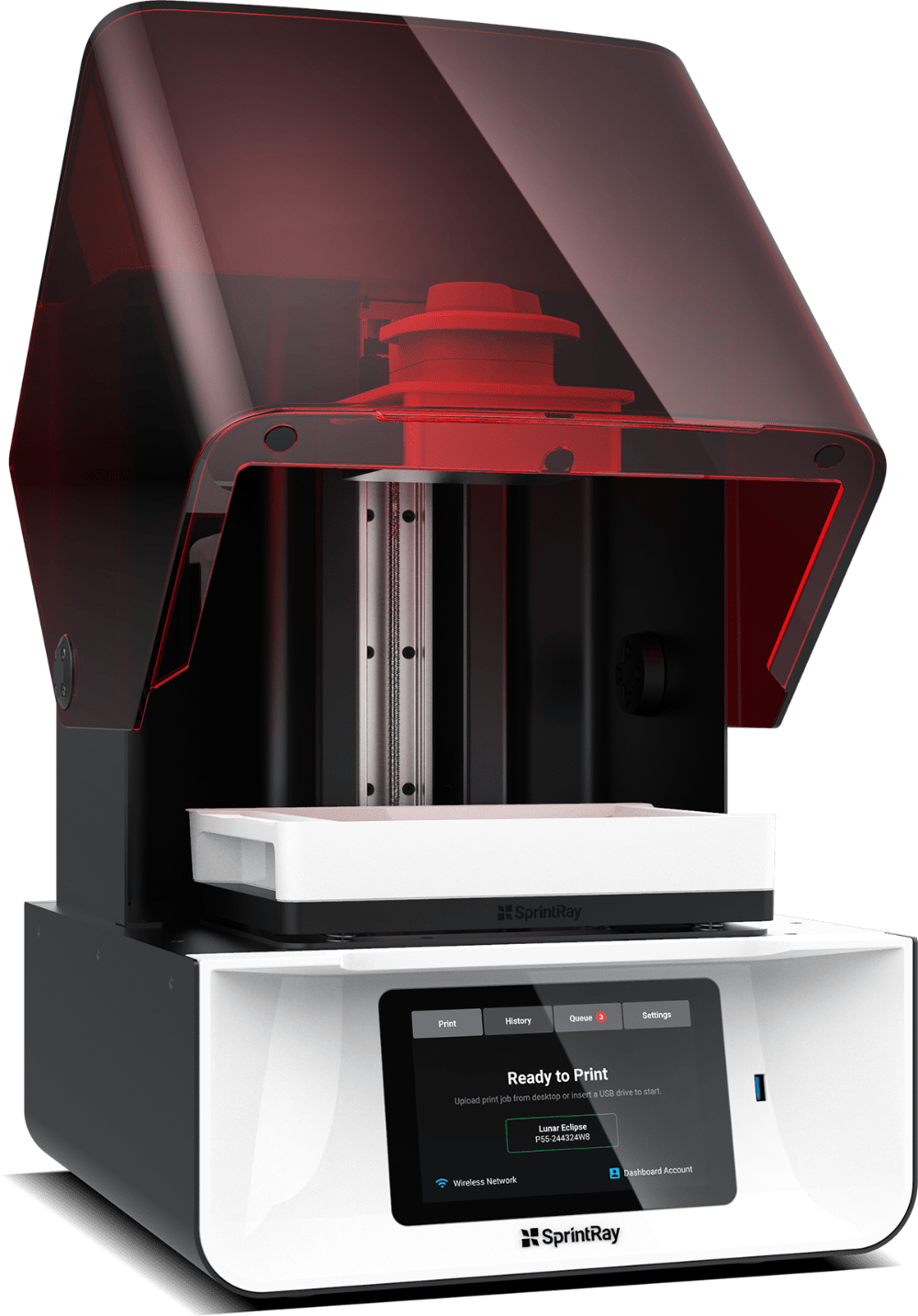

Design and Engineering

Beauty meets brawn.

Objects of quality should stand the test of time, and dental tools must be as durable as they are beautiful. SprintRay Pro is built with the finest materials: an aluminum chassis, super-strong PMMA polymers, tempered glass, and magnetic locks. Because little details make a big difference.

Behind the aesthetic design lies a highly-advanced, durable desktop 3D printer backed by smart, intuitive software.

Aluminum Chassis

SprintRay Pro is built using performance manufacturing techniques. It is cast in lightweight, super-strong aluminum and then machined for extreme accuracy and long-term production durability.

Cast and Machined

Magnetic Attraction

For foolproof operation, a magnetic lock on the build platform ensures perfect build plate orientation. A second magnet senses when the lid is open, reducing the risk of exposing resin to ambient light.

Patented MagSwitch®

Onboard Computer

Your always-on printing expert guides you through the print process.

6-Core CPU with GPU

Productivity Boost

Powerful 5GHz wifi module for unmatched power and connectivity.

5GHz Wi-Fi Chipset

Self-Monitoring

Smart thermal management of SprintRay Pro’s resin tank ensures optimal resin temperature.

IR and Ambient Sensors

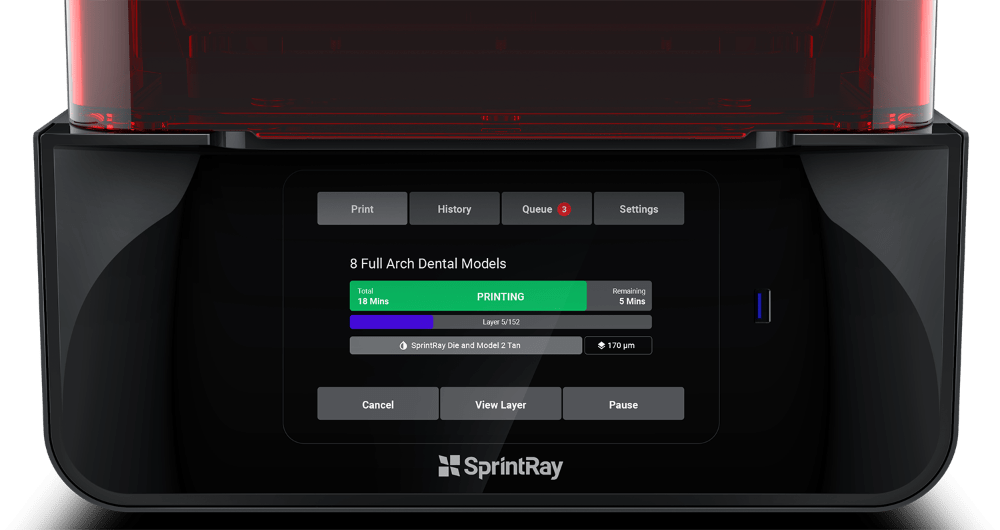

Your new dental production assistant.

The custom 7” touchscreen on SprintRay Pro manages your prints, resin levels, and calibration. It also provides contextual help and instructional videos, so that you can focus on using your 3D printer to provide high-quality dental care.

SprintRay Pro Dental 3D Printer

Ready for today, built for tomorrow.

Own the Future

SprintRay Pro is always connected, incredibly fast, and easy to use. With future-proof features like over-the-air updates and a 7” touchscreen, it’ll be on the cutting-edge for a generation. And with SprintRay’s incredible support staff, printing has never been so hassle-free.

Plug and Play

SprintRay Pro comes standard with everything you need to start printing, including a quick-start guide and tools to take you from digital model to finished product.

Compare

Pro 95 |

Pro 55 |

|

|---|---|---|

| Build Platform Area | 1836cm (180mm x 102mm) | 619cm (105mm x 59mm) |

| Minimum Feature Size | 95um + Pixel Toning | 55um + Pixel Toning |

| Print Speed | Up to 3 Inches per Hour | Up to 3 Inches per Hour |

| Supported Resin Brands | SprintRay, NextDent, Dreve, Bego, DENTCA, KeyStone | SprintRay, NextDent, Dreve, Bego, DENTCA, KeyStone |

| Live Support | Phone Setup Consultation, Free Lifetime Phone & Email Support | Phone Setup Consultation, Free Lifetime Phone & Email Support |

| Onboard Computer | Direct USB Printing, Contextual Help, Print Monitoring | Direct USB Printing, Contextual Help, Print Monitoring |

| Recommended Indications | Full-arch Surgical Guides, Waxup Models, Retainer Models, Study Models, Occlusal Guards, Indirect Bonding Trays | Indirect Restorations, Die Models, Implant Dentures, Full-arch Surgical Guides, Temporaries, Cast Applications |

| Target Segment | General Practitioners, Oral Surgeons | Labs, Restorative Dentists, Prosthodontists |