In-Office 3D Printing of Surgical Guides

SprintRay 3D printers help dental professionals improve outcomes and practice efficiency. Print surgical guides in-office, reducing the cost and turnaround time for guided surgery. With dedicated support and a full printing ecosystem including the Pro Cure post-processing system and RayWare printing suite, SprintRay is your partner for in-office manufacturing.

In-Office Surgical Guides

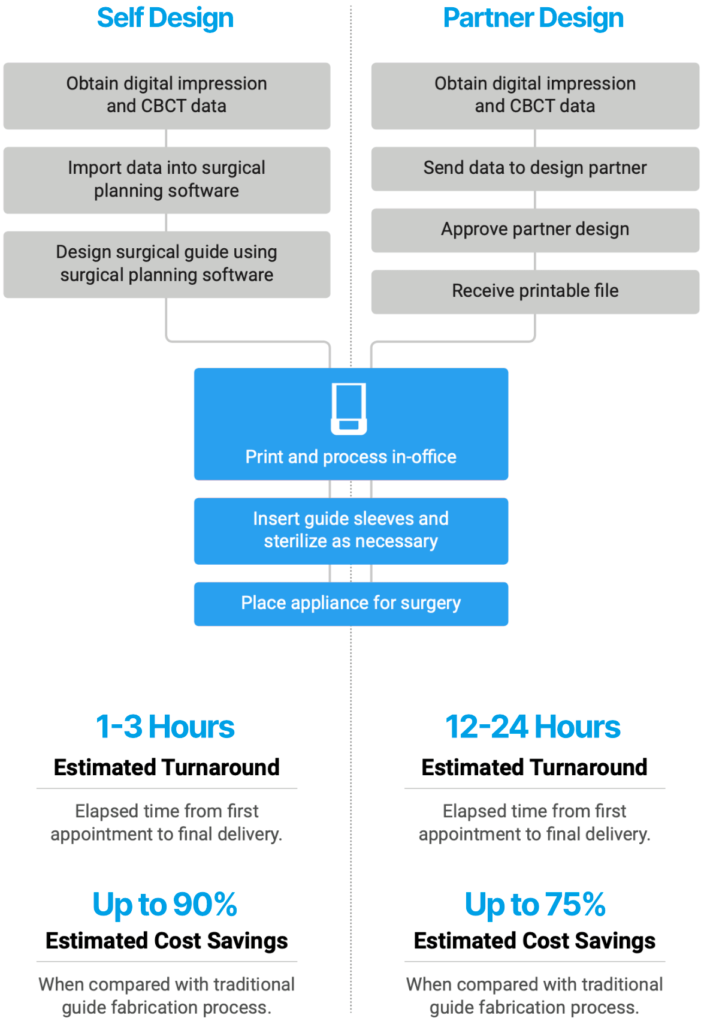

Offer guided surgery without the fees or long lead times that come with traditional guide fabrication. 3D print surgical guides in-office in a half hour, shortening treatment times while improving patient experience and chance of surgical success.

Key Benefits

- Reduce time between diagnosis and surgery

- Gain full control over treatment planning

- Offer guided surgery with decreased costs

- Print full-arch and quadrant guides rapidly

Suitable Resins

KeyPrint

KeyGuide

Shining 3D Surgical Guide SG01