In-Office 3D Printing of Indirect Bonding Trays

SprintRay 3D printers help dental professionals improve outcomes and practice efficiency. Print indirect bonding trays in-office, drastically reducing chair time for orthodontic bracket placement. With dedicated support and a full printing ecosystem including the Pro Cure post-processing system and RayWare printing suite, SprintRay is your partner for in-office manufacturing.

In-Office Indirect Bonding Trays

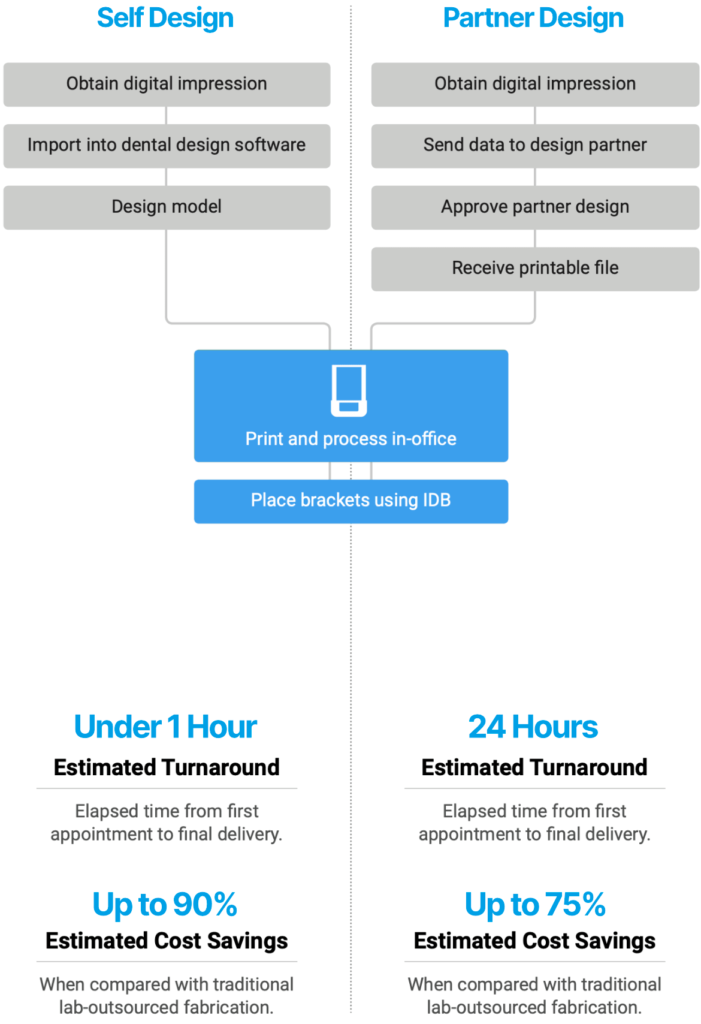

Indirect bonding trays improve patient experience by drastically reducing chair time for bracket placement appointments. Producing them in-house means you don’t have to wait for your lab to design and ship, increasing flexibility and speed. Design the appliance yourself or use a design partner and print the final model.

Key Benefits

- Place full arch of brackets in 5 minutes

- Increase accuracy of bracket placement

- Improve patient comfort

- Design and print IDB in under an hour

Suitable Resins