In-Office 3D Printing of Digital Dentures

SprintRay 3D printers help dental professionals improve outcomes and practice efficiency. Print digital dentures in-office, reducing the cost and duration of the denture delivery process. With dedicated support and a full printing ecosystem including the Pro Cure post-processing system and RayWare printing suite, SprintRay is your partner for in-office manufacturing.

In-Office Digital Dentures

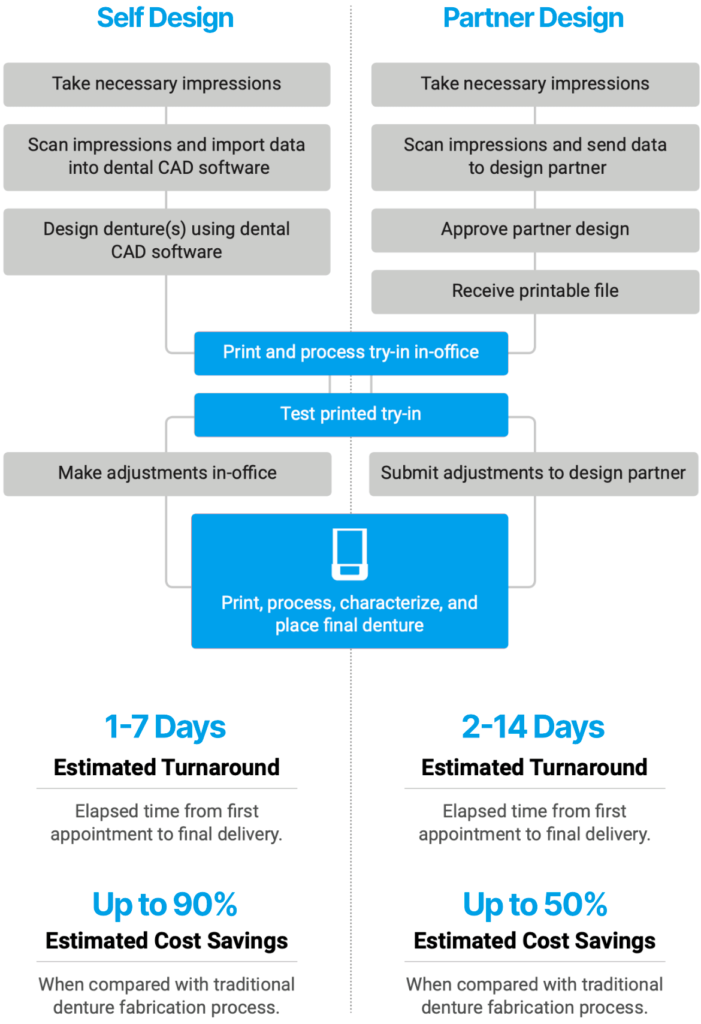

3D printing dentures in-office can drastically reduce the duration

from first appointment to final placement and give patients a reliable, immediate solution. Outsource the design for a nominal fee and print the final product or handle the design in-office. With 3D printing, you can fabricate monolithic try-ins, short-term temporaries, and final dentures, all in a matter of hours.

Key Benefits

- Reduce the number of appointments required

- Simplify the fabrication and repair processes

- Improve margins, particularly for low-cost cases

- Print confidently with FDA-compliant materials

Suitable Resins